Wear and Abrasion Resistant Compounds

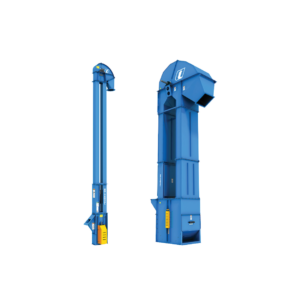

For all high wear and erosion areas in the plant process with various specifications from water, slurry, aggregate transportation to protection from acid and chemicals.

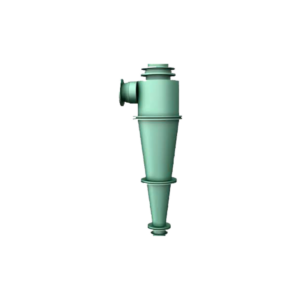

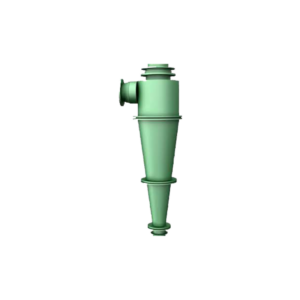

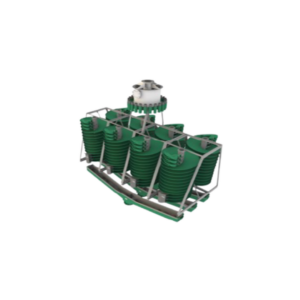

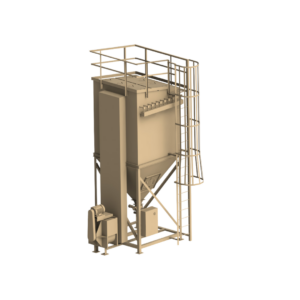

For the lining of pipes, pipe bends, chutes, pumps, tank walls, agitator blades, cyclones, splitter and distribution boxes, launders, de-watering bins and granulation bins.

7kg Part number 7459-6145

NORDBAK® NORDTILE is a co-polymer trowelable monolithic paste with excellent wear properties, resilience, high impact strength and chemical resistance. This product can be applied seamlessly on new equipment or as a patch repair on worn areas with minimum downtime.

This product is also heavily filled with high-density fillers to assist with heat dissipation.

NORDTILE is designed specifically for :

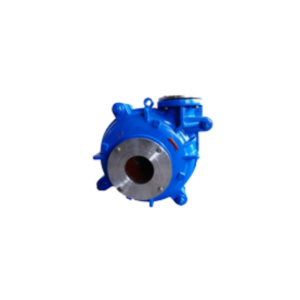

- Slurry pump casings

- Chutes

- High-wear abrasion applications

- Suitable for both waterborne slurries and pneumatic conveyancing

- Additionally, NORDTILE can be used to smooth edges where conventional tiles join or have fallen out

- Temperature limit of 200°C continuous for pneumatic flow. Immersion temperature is dependent on contents

Technical Information:

- Acid resistance (immersion at ambient temperature) Sulphuric acid 50%

- Hardness 80 Shore D DIN 53 505

4 x 1kg Part number 7459-6146

NORDBAK® NORTILE FS is a fast-curing co-polymer trowelable monolithic paste with excellent wear properties, resilience, high impact strength and chemical resistance.

The Fast set variant has been designed for fast curing and quick repair applications.

NORDTILE FAST SET (FS) is designed specifically for:

-

Slurry pump casings

-

Chutes

-

High-wear abrasion applications

- Suitable for both waterborne slurries and pneumatic conveyancing

-

Additionally, NORDTILE FASTSET (FS) can be used to smooth edges where conventional tiles join or have fallen out

- Temperature limit 200°C continuous for pneumatic flow. Immersion temperature is dependent on the contents

The Fast Set variant has been designed for fast curing.

Technical Information:

- Acid resistance (immersion at ambient temperature) Sulphuric acid 50%

- Hardness 80 Shore D DIN 53 505

10kg Part number 7459-6152

NORDBAK® NORDWEAR 8 has excellent wear properties, resilience, high impact strength and chemical resistance. It is also heavily filled with high-density fillers to assist with heat dissipation.

NORDWEAR 8 is designed specifically for:

- Suitable for both waterborne slurries and pneumatic conveyancing.

-

Pump casings

-

Chutes

-

High-wear applications in chrome reduction plants.

Temperature limit 200°C continuous for pneumatic flow. Immersion temperature is dependent on contents.

Technical Information:

- Acid resistance (immersion at ambient temperature) Sulphuric acid 50%

- Hardness 90 Shore D DIN 53 505

- Should be applied at a minimum thickness of 6mm for best results.

12.5kg product number 7459-9959

NORDBAK® HIGH-IMPACT WEARING COMPOUND was designed primarily for patching and relining pump casings. Will bond to all types of wear metal with proper surface cleaning.

High-Impact Wearing Compound can be used in:

- Conveyor skirts

- Feed chutes

- Wear plates

- Slurry lines

- Pipe elbows

- Patching and relining pump casings

Wherever high wear and high impact conditions have been wearing away production profits.

Technical Infromation:

- Compressive strength 103 MPa

- Curing is complete in 3 – 4 hours @ 25°C

10kg Part number 7459-6150

- Acid resistance (immersion at ambient temperature) Sulphuric acid 50%

- Temperature limit 200°C continuous for pneumatic flow. Immersion temperature is dependent on contents.

- Hardness 85 Shore D DIN 53 505

NORDBAK® NORDWEAR 5 contains fillers with exceptional abrasive, chemical and corrosion resistance. Suitable for both waterborne slurries and pneumatic conveyancing.

NORDWEAR 5 is suitable for:

- Waterborne slurries

- Pneumatic conveyancing

10kg Part number 7459-6154

- Impact strength 3.4 Jm-1

- Suitable for both waterborne slurries and pneumatic conveyancing

- Working time 10 minutes @ 25°C

NORDBAK® NORDWEAR 5 FS contains fillers with exceptional abrasive, chemical and corrosion resistance and these fillers assist with heat dissipation.

The Fast set variant has been designed for fast curing and quick repair applications.

NORDWEAR 5 FAST SET (FS) is suitable for:

- Waterborne slurries

- Pneumatic conveyancing

The Fast Set variant has been designed for fast curing and quick repair applications.

10kg Part number 7459-6201

4 x 1kg Part number 7459-6203

- Acid resistance (immersion at ambient temperature) to Sulphuric Acid 50%

- Hardness 85 Shore D DIN 53 505

NORDBAK® NORDWEAR 5 ACID contains fillers with exceptional abrasive, chemical and corrosion resistance. Suitable for both waterborne slurries and pneumatic conveyancing.

NORDWEAR 5 ACID is specifically designed for:

Vanadium Plants where there are high levels of salts (sodium sulphate, ammonium sulphate and vanadium pentoxide are present at pH values between 3 and 10)

NORDWEAR 5 ACID is suitable for:

- Waterborne slurries

- Pneumatic conveyancing

- Temperature limit 200°C continuous for pneumatic flow. Immersion temperature is dependent on the contents

12.5kg product number 9505-9938

- Compressive strength 100 MPa

- Curing is between 6-8 hours @ 25°C

NORDBAK® STANDARD WEARING COMPOUND contains sapphire hard alumina ceramic beads in co-polymer resin. The irregular beads take the wear and prolong the life of the base metal. It conforms to any shape including curved surfaces such as cones and elbows. The use of this advanced material cuts downtime to a minimum.

STANDARD WEARING COMPOUND is ideal for high-wear areas caused by solids and slurries and can conform to any shape including curved surfaces such as cones and elbows. It can be used wherever high wear conditions have been wearing production profits.

STANDARD WEARING COMPOUND can be applied to:

- Idlers

- Sheaves

- Pump Casings

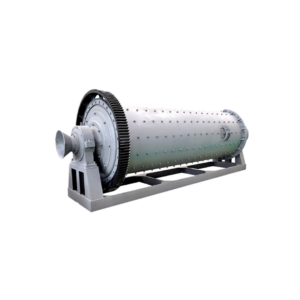

- Rod and Ball Mills

- Pan Feeders

- Buckets

- Conveyor Skirts

- Feed Chutes

- Wear Plates

- Slurry Lines

- Pipe Elbows

10kg product number 9000-0110

- Compressive strength 100 MPa

- Ideal armour-surfacing high-wear areas caused by solids and slurries

- Curing is complete in 6 – 8 hours @ 25°C

NORDBAK® FIXWEAR was designed primarily for patching and relining pump casings. Will bond to all types of wear metal with proper surface cleaning.

FIXWEAR can also be used in the following areas:

- Conveyor skirts

- Feed chutes

- Wear plates

- Slurry lines

- Pipe elbows

Wherever high wear and high impact conditions have been wearing away production profits.

4 x 1kg product number 9000-0141

- Fast curing trowelable wearing compound

- Compressive strength 100 MPa

- Ideal armour-surfacing high-wear areas caused by solids and slurries

- Curing is complete in 2 – 3 hours @ 25°C

NORDBAK® FIXWEAR FS was designed primarily for patching and relining pump casings. Will bond to all types of worn metal with proper surface cleaning.

The Fast Set variant has been designed for fast curing and quick repair applications.

FIXWEAR FASTSET (FS) can also be used in the following areas:

- Conveyor skirts

- Feed chutes

- Wear plates

- Slurry lines

- Pipe elbows

Wherever high wear and high impact conditions have been wearing away production profits.

12kg product number 7459-9838

- Full curing in 4 – 6 hours @ 25°C

- Excellent for the repair of pneumatic conveying systems

- No special tools or equipment are required

NORDBAK® STANDARD PNEU-WEAR is a trowelable wear-resistant coating designed for pneumatic applications for fine particle abrasion. Contains miniature irregular ceramic beads to provide high-efficiency wear protection.

STANDARD PNEU-WEAR is excellent for repair to pneumatic conveying system where there is fine particle abrasion.

12kg product number 7459-9837

- Full curing in 8 hours @ 25°C

- Excellent for the repair of pneumatic conveying systems

- No special tools or equipment are required

- 130°C continuous for pneumatic flow

NORDBAK® HIGH-TEMPERAURE PNEU-WEAR is a trowelable wear-resistant coating designed for high-temperature pneumatic applications for fine particle abrasion. Contains miniature irregular ceramic beads to provide high-efficiency wear protection.

HI-TEMP PNEU-WEAR is excellent for repair to pneumatic conveying system where there is fine particle abrasion.

6 x 1kg Black product number 8110-0200

6 x 1kg Blue product number 8110-0201

NORDBAK® NORDCOAT 2 is an outstanding heavy-duty corrosion, acid, wear-resistant coating with superior wear-abrasion properties that can be applied to steel and a wide variety of other substrates.

NORDCOAT 2 is a two-part 100% solids co-polymer coating giving maximum coating thickness in a one-coat application.

Final cure time 6 hours @ 20°C

NORDCOAT 2 can be used in the following areas:

- Steel

- Concrete

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

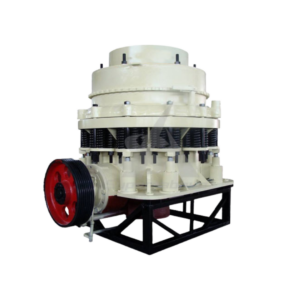

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery.

STANDARD BACKING is tough, resilient and ideal for Gold, Copper and Low Strength Ores Cone Crushers (5 foot Crushers), Primary Gyratory Crushers, Rotating Mills, Pulverizes and other heavy reduction machinery. NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.

NORDWEAR 5 has excellent wear properties together with resilience and impact strength. It has been designed specifically for Waterborne Slurries and Pneumatic Conveyancing.